Binder Jetting: A High-Potential 3D Printing Process

11 Jun 25

Articles

Reading time: 3 minutes

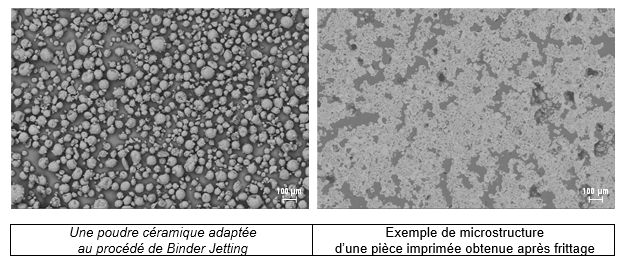

Binder Jetting technology operates by building parts layer by layer through the selective deposition of a binder onto a powder bed to bond the particles together. Once printed, the "green" part is depowdered, then debound and sintered.

Advantages of the Binder Jetting Process

Binder Jetting technology offers a number of advantages that make it a rapidly evolving solution for industrial applications.

Currently, several machine manufacturers offer large-format systems equipped with multiple printheads, enabling high-speed printing and scaling up to industrial production. The absence of lasers also makes Binder Jetting machines more affordable than those used for SLA (Stereolithography) or SLM (Selective Laser Melting) processes.

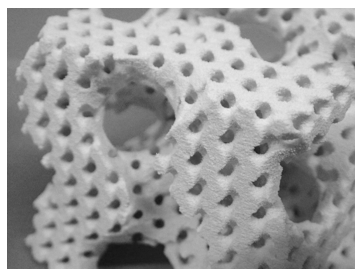

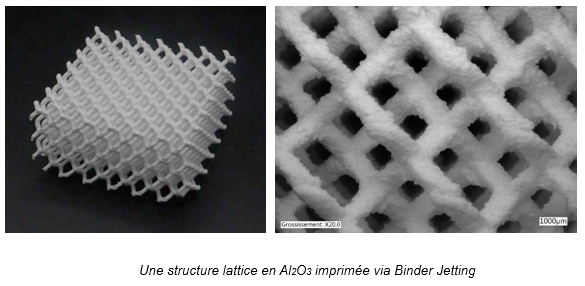

The potential of this ceramic 3D printing technology also lies in its broad design freedom, as parts can be printed without the need for support structures. The printed object is self-supported by the surrounding powder within the build chamber. Unlike the Selective Laser Sintering (SLS) process, Binder Jetting induces fewer residual stresses during printing. Another advantage is the reusability of the unbound powder for future prints, contributing to more sustainable material usage.

Binder Jetting is particularly well-suited for producing parts with high porosity, typically ranging from 20% to 60%. One of the key benefits of this technology is the ability to control porosity levels, both in shape and microstructure. In some cases, an additional infiltration step can be applied to reduce porosity and enhance mechanical properties.

Sectors, applications and materials

The ability to create freeform shapes using Binder Jetting technology is currently of great interest to traditional ceramics manufacturers, as well as professionals in the arts, model making, and education sectors.

A wide range of silicate-based materials (such as silicates, porcelain, earthenware, stoneware...) or plaster can be used for this purpose.

As a result, Binder Jetting opens up new possibilities and solutions in fields where ceramics are used as construction, refractory, or insulating materials.

One of the sectors most interested in this technology is the medical field. Biomaterials such as OCP (octacalcium phosphate), HAP (hydroxyapatite), TCP (tricalcium phosphate), calcium sulfate, LAS (lithium aluminosilicate), bioactive glasses, and silicon nitride are of great interest for custom-shaped medical applications.

Research has been conducted for many years to test, develop, and validate the process for printing ceramic orthopedic prostheses and implants.

Parts printed using Binder Jetting can also be used in various industrial sectors. The unique properties of technical ceramics produced through this technology can be harnessed in fields such as chemistry, automotive, aerospace, space, nuclear, electronics, and defense.

A wide range of applications is possible — from filters and membranes, heat exchangers, and catalyst supports, to foundry cores and skeletal supports for metal matrix composites.

Depending on the application, the raw material formulations are selected from oxide ceramics (such as Al₂O₃, ZrO₂, TiC/TiO₂, SiO₂, cordierite, BaTiO₃, etc.) or non-oxide ceramics (such as SiC, Si₃N₄, etc.).

Nos précédents articles sur les céramiques techniques

Thanks and partnerships

The CTTC would like to thank the European Union and the Nouvelle-Aquitaine Region for their confidence and financial support.