Center for Technology Transfers in Ceramics

Ceramic Innovation for Industry

+

1000

projects f

+400

customers

+

90

equipment

92

%

level of satisfaction

Since 1984

Our missions

As an association, the CTTC carries out missions of general interest to companies. It applies/develops, alone or in collaboration, ceramic shaping technologies that can be transferred industrially.

On the one hand, its strong links with academic research enable it to keep in touch with the state of the art in science and to position itself in the maturation of high-potential technologies, and on the other hand to offer industry its resources, expertise and the skills of its team.

Services

Our services

From materials characterisation to process industrialisation, including prototyping and training, the CTTC offers a wide range of services.

Our values

Whether it's our private activities (serving our customers), our collaborative activities (responding to a common need), or our internal developments (in the public interest), we are driven by the same values of responsiveness, flexibility, integrity and professionalism.

Our multi-skilled team is made up of men and women who are experts in their fields, combining their skills to meet both the demands expressed by our customers and the economic, social and environmental challenges we now face.

Thanks to our know-how, our experience feedback and the range of technologies at our disposal, we can turn ideas into reality while covering a wide range of needs, within deadlines adapted to our customers' and partners' deadlines and in strict compliance with confidentiality rules.

Reactivity

Flexibility

Professionnalism

Integrity

Our resources

Technological platforms

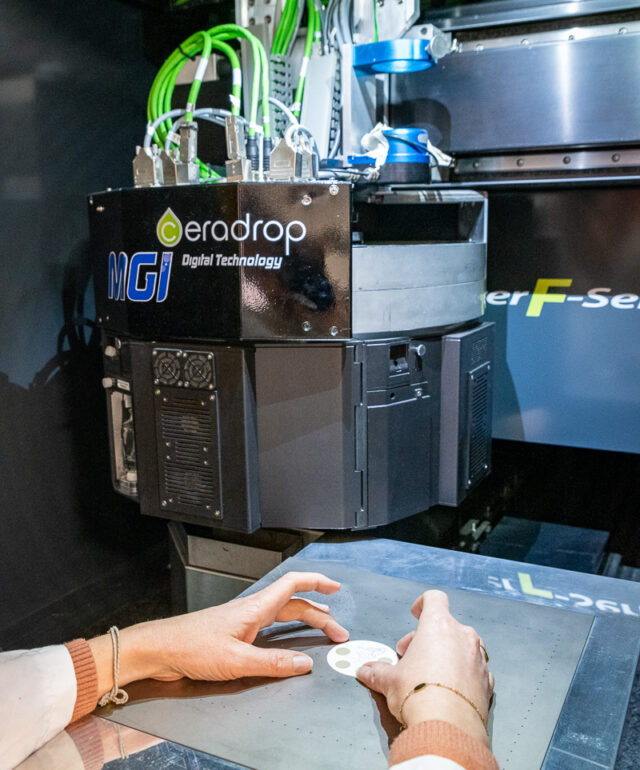

Advanced manufacturing

Our CERATECH by CTTC platform gathers a range of resources for the manufacturing of technical ceramics or multi-material.

Additive manufacturing

Our ALTERINOV by CTTC platform comprises a dozen printers, applying single or hybrid process for 3D printing or direct ink writing.

Blog

Our news

They share their experiences

We've only worked with the CTTC once, in order to solve a technical problem involving the durability of ceramic parts. The CTTC quickly assessed our parts and gave us the right solutions to eradicate our breakage problem [...] which had a very positive impact on our customers.

The people I dealt with at the CTTC demonstrated great expertise, excellent responsiveness and a very good sense of customer relations.

The results of CTTC's action, 6 months later, are clearly positive. We have identified new ways of developing our products and strengthened the quality of our customer/supplier relationships.