Training

Enabling the acquisition of new skills

As a certified training organisation, by the French government, the CTTC makes its skills available to you, through ongoing training courses combining theory and practice. These courses cover conventional ceramic shaping processes (dry, plastic and liquid), additive manufacturing processes, characterisation or heat treatment of ceramics.

Objectives

Acquire specific skills to improve understanding of the use of ceramic materials, or better manage their manufacturing processes.

Who should attend?

Engineers or technicians who produce, use or wish to use ceramics.

Access for people with disabilities: the course can be adapted to meet the needs of people with disabilities by contacting us (see contact details below); access to our facilities is specifically designed to meet the needs of people with reduced mobility.

The Courses

- According to a catalogue or tailor-made program

- At the CTTC or on site (by adapting the training content)

- Procedure: teaching methods encourage trainee participation by creating small groups of trainees (6 to 8 people to the maximum) and carrying out practical work using CTTC’s equipment

- Access: face-to-face in the CTTC's facilities

We offer a wide range of training courses in the form of theoretical presentations and practical trials on our industrial equipment, enabling you to discover the specific features of the manufacture and use of ceramics.

88

%

Trainees satisfaction

84

%

Acquisition for trainees skills

They share their experiences

Thank you again for this qualitative practical and theoretical training.

Thank you once again for this superbly informative and lively course!

Thank you once again for this superbly great course, very informative enriching and lively course!

Our training modules

MOD 5: Dry shaping of ceramics (spray drying, pressing)

Objectives

- Describe the atomisation process in detailS and explain its advantages

- Describe the various components of a spray dryer and their respective roles

- Make the link between suspension formulation and operating parameters to optimise granule properties

- Select a pressing process according to the required geometry of the part

- Identify the important operating parameters to avoid pressing defects

Teaching

- Theoretical courses

- Practice work on CTTC's equipment

People concerned

- Engineers and technicians

Pratical Information

Location: CTTC Limoges

Date: 12(AM) - 13 and 14(M) September 2023

Price: €1,800 excluding VAT (meals included)

Duration: 2 days

Module number: 5

MOD 6: Plastic shaping of ceramics (injection, extrusion)

Objectives

- Describe the different steps in the manufacture of an injected part or extruded part

- Identify the type of additives to be used in the preparation of a plastic ceramic paste and know their average content

- Determine the analyses required to formulate a plastic paste

- Adapt a heat treatment cycle for a shaped ceramic part

Teaching

- Theoretical courses

- Practical work on CTTC's equipment

Teaching

- Theoretical courses

- Practice work on CTTC equipment

People concerned

- Engineers and technicians

Pratical Information

Location: CTTC Limoges

Date: 5(AM) - 6 - 7 and 8(M) December 2023

Price: €2,700 excluding VAT (meals included)

Duration: 3 days

Module number: 6

MOD 8: Technical ceramics: associated materials and processes

Objectives

- Identify the additives to be used and their average content requirement in different shaping technologies

- Describethe different steps in the manufacturing of a ceramic part shaped using dry, liquid and plastic processes

- Adapt a heat treatment cycle for a shaped ceramic part

- Identify the suitable characterisation method to determine the desired property of a ceramic powder or bulk

- Set the properties to be reached for a ceramic material for a given application

Teaching

- Theoretical courses

- Practice on CTTC's equipment

People concerned

- Engineers and technicians

Pratical Information

Location: CTTC Limoges

Date: 21(AM) - 22 - 23 and 24(M) November 2023

Price: €2,700 excluding VAT (meals included)

Duration: 3 days

Module number: 8

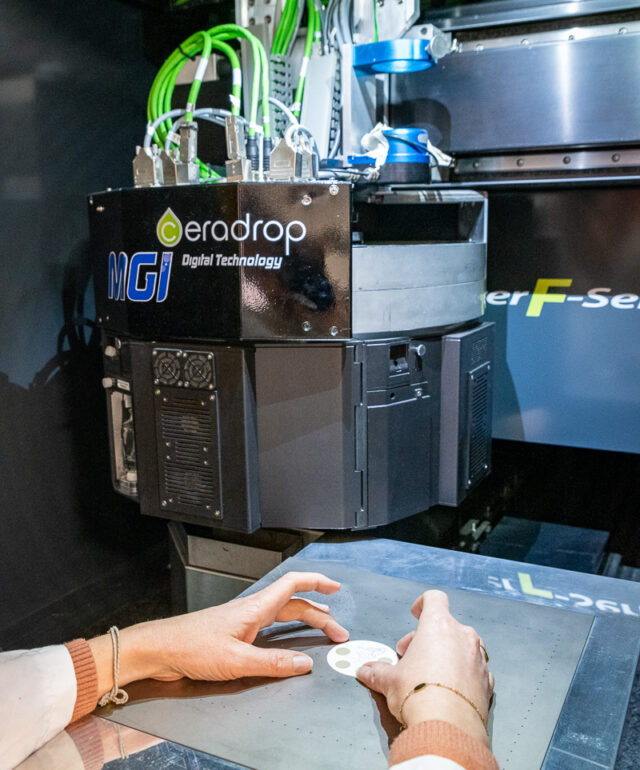

MOD 11: Additive manufacturing of ceramic materials: from design to product

Objectives

- Describe the different steps involved in producing a ceramic part using different additive manufacturing processes

- Trace the different steps of the digital chain with the associated tools

- List the advantages and drawbacks of the different additive manufacturing technologies for ceramic materials

- Determine how to develop a product through a case study

Teaching

- Theoretical courses

- Practice work on CTTC's equipment

People concerned

- Production and/or R&D engineers

- Technicians

Pratical Information

Location: CTTC Limoges

Date: 19(AM)-20 - 21 and 22(M) September 2023

Price: €2,700 excluding VAT (meals included)

Duration: 3 days

Module number: 11